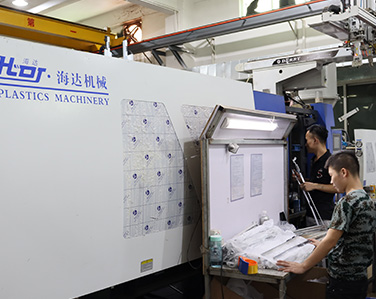

Located in Qingxi Town, Dongguan City, Guangdong Province, the company covers an area of about 4000 square meters and introduces advanced production equipment and testing equipment at home and abroad; It is equipped with independent mold manufacturing workshop, silk screen printing workshop, injection molding workshop, inspection and packaging workshop, more high-quality management and technical personnel, and has perfect process and production process from engineering R & D to mold manufacturing, silk screen printing, injection molding and inspection and packaging.

The company's R & D and production: 3C digital electronic products, home appliance panels, intelligent household products, electrical switches, toy parts, intelligent floor sweeper vacuum cleaner, intelligent fingerprint lock panel, personal care beauty salon instruments, modified car shell, medical small shell, plastic shell around computer, etc. Adhere to the pure quality of materials, after continuous efforts and struggle, it has developed into a mold / injection molding manufacturer highly recognized by customers

Quenching can improve the quality of plastic molds and is a heat treatment technology often used in processing. Quenching mainly involves heating the metal material to a temperature sufficient to cause phase change and then keeping it warm, then rapidly cooling it at a rate greater than the critical cooling rate to obtain a martensitic structure, and then tempering it at different temperatures to obtain the required mechanical properties. The quenching temperature should take into account the shape, size and original structure of the mold.

more

The annealing treatment of plastic molds is mainly to eliminate the internal stress caused by various reasons, so that the quality of the parts meets the use standards, there are no obvious defects in the appearance, and the performance of the mold steel is improved to facilitate the subsequent processing procedures. Annealing can make the metal structure inside the mold more stable and balanced, ensuring the quality of subsequent processing and final heat treatment. Annealing is the pearlite in the mold metal.

more

Due to various unfavorable factors, the injection mold causes cracking of the drawn parts, which is a very serious appearance defect. Too many defective products or even complete scrapping greatly wastes raw materials and reduces production efficiency, wasting resource loss. How to solve this situation? The pressing surface is unevenly colored and poorly polished, the pressing ribs are damaged, and the length of the mold support is not the same after installation.

more

QR code attention

Shenye plastic